Burying a forged wind turbine shaft just doesn’t make sense. The materials used in these shafts are incredibly durable, which makes them resistant to degradation when buried. However, this durability poses environmental risks. Imagine the potential for soil contamination or impacts on groundwater. Plus, there are legal implications tied to waste management that we must consider. As one of the leading forged wind turbine shaft suppliers, including those from Rongli Forging Co., Ltd, I can’t stress enough the importance of finding responsible solutions for disposal of china forged wind turbine shafts.

Key Takeaways

- Burying forged wind turbine shafts can lead to soil contamination and groundwater issues, posing serious environmental risks.

- Recycling forged wind turbine shafts is a responsible alternative that recovers valuable materials and reduces waste.

- Compliance with waste management laws is crucial to avoid hefty fines and legal troubles when disposing of industrial materials.

- Understanding the material properties of forged wind turbine shafts helps ensure their durability and safety in wind energy systems.

- Exploring innovative disposal solutions is essential as more wind turbines reach the end of their life, promoting sustainability in the industry.

Forged Wind Turbine Shaft Material Properties

When we talk about forged wind turbine shafts, one of the first things that come to mind is their impressive material properties. These shafts are built to withstand harsh conditions, and two key aspects stand out: corrosion resistance and structural integrity.

Corrosion Resistance

Corrosion can be a significant issue for any metal structure, especially those exposed to the elements. Fortunately, forged wind turbine shafts are made from materials that offer excellent corrosion resistance. Commonly used materials include alloy steel and stainless steel.

- Nickel improves toughness and ductility.

- Molybdenum enhances strength and hardenability.

These elements work together to ensure that the shafts can endure the rigors of wind and weather without succumbing to rust or degradation. This durability is crucial, as it means less maintenance and longer lifespans for the turbines.

Structural Integrity

The structural integrity of a forged wind turbine shaft is vital for its performance and safety. These shafts must handle immense loads and stresses while remaining stable. The typical chemical compositions of the materials used in these shafts contribute to their strength and resilience.

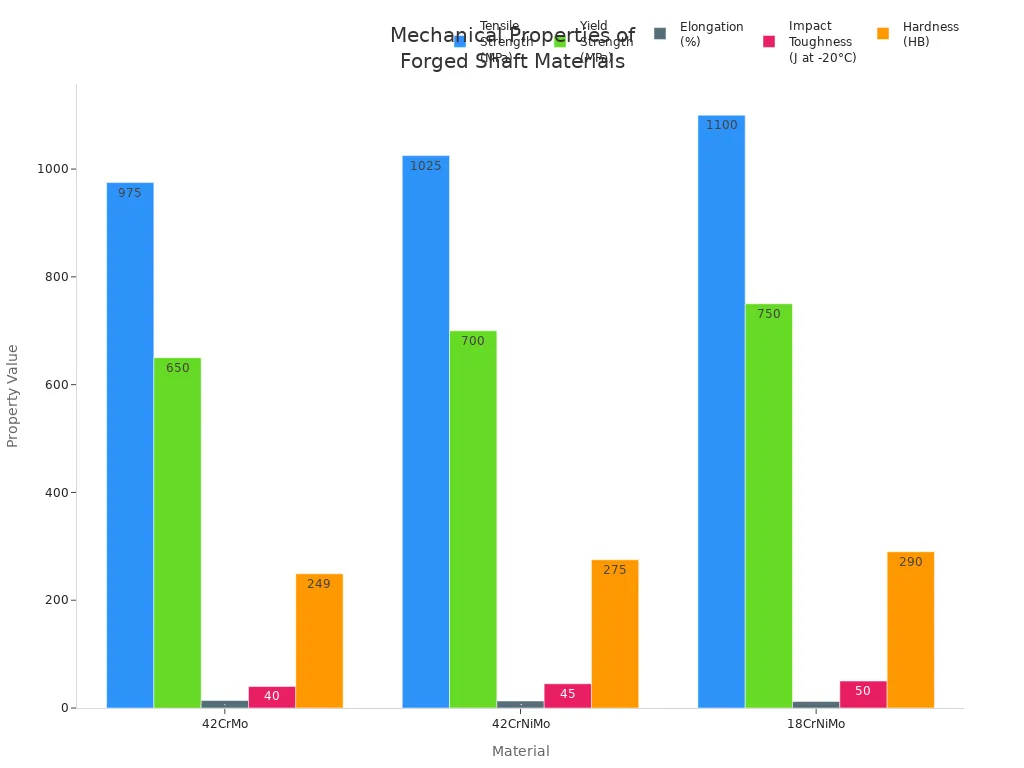

Here’s a quick look at some common materials and their properties:

| Property | 42CrMo | 42CrNiMo | 18CrNiMo |

|---|---|---|---|

| Tensile Strength | 850–1100 MPa | 900–1150 MPa | 1000–1200 MPa |

| Yield Strength | ≥ 650 MPa | ≥ 700 MPa | ≥ 750 MPa |

| Elongation | ≥ 14% | ≥ 13% | ≥ 12% |

| Impact Toughness | ≥ 40J (at -20°C) | ≥ 45J (at -20°C) | ≥ 50J (at -20°C) |

| Hardness (HB) | 229–269 | 248–302 | 270–310 |

These properties ensure that the forged wind turbine shafts maintain their shape and strength under pressure. The combination of high tensile and yield strength, along with good elongation and impact toughness, makes these shafts reliable components in wind energy systems.

Environmental Concerns of Forged Wind Turbine Shafts

When I think about burying forged wind turbine shafts, I can’t help but worry about the environmental consequences. Two major concerns stand out: soil contamination and groundwater impact. Let’s dive into these issues.

Soil Contamination

Burying these shafts can lead to serious soil contamination. The materials used in forged wind turbine shafts are incredibly durable, but that durability can become a problem when they degrade. If the shafts break down, they can release harmful substances into the soil.

Here are some potential risks I’ve come across:

- High levels of radionuclides and heavy metals can seep into the ground.

- Residents who grow vegetables in contaminated soil may face health complaints like dermatitis, chronic cough, and wheezing.

- Vulnerable populations, especially those with weakened immune systems, could experience increased carcinogenic risks due to exposure to heavy metals.

These risks highlight why we should think twice before considering burying forged wind turbine shafts. The last thing we want is to harm our soil and, ultimately, our health.

Groundwater Impact

Now, let’s talk about groundwater. When contaminants leach into the soil, they can easily make their way into our water supply. This is a serious concern because groundwater is a vital resource for drinking water and irrigation.

Imagine the consequences if toxic substances from buried shafts enter our aquifers. It could lead to widespread health issues and affect entire communities. Protecting our groundwater is essential, and burying forged wind turbine shafts poses a significant risk to this precious resource.

Legal Issues Surrounding Forged Wind Turbine Shaft Disposal

When it comes to disposing of forged wind turbine shafts, legal issues play a significant role. I’ve learned that compliance with waste management laws is crucial. Ignoring these regulations can lead to serious consequences.

Waste Management Compliance

Non-compliance with waste management laws can result in hefty penalties. For instance, the Environmental Protection Agency (EPA) can impose fines of up to $70,117 per violation, per day for continued non-compliance. That’s a staggering amount! I remember reading about a case where Walmart had to pay $7.5 million to settle a lawsuit over improper hazardous waste disposal. This shows how important it is to follow the rules when it comes to disposing of industrial metal waste like forged wind turbine shafts.

Tip: Always check local regulations before disposing of any industrial materials. It can save you from costly fines and legal troubles.

Environmental Protection Laws

Several environmental protection laws specifically address the disposal of wind turbine components. Here’s a quick look at some key legislation across different states:

| State | Focus of Legislation | Key Points |

|---|---|---|

| Texas | Wind turbine waste management and recycling | Developing sustainable disposal methods and defining decommissioning criteria for wind farms. |

| Oklahoma | Procedures for decommissioning wind energy facilities | Mandates removal of deactivated turbines and explores responsible waste handling methods. |

These laws aim to ensure that we handle forged wind turbine shafts responsibly. They promote recycling and proper disposal methods, which are essential for protecting our environment.

In my experience, understanding these legal frameworks is vital for anyone involved in the wind energy sector. It helps us make informed decisions and avoid potential pitfalls.

Alternative Solutions for Forged Wind Turbine Shafts

When it comes to dealing with forged wind turbine shafts, I believe we should focus on responsible alternatives. Recycling and proper disposal techniques can help us minimize waste and protect the environment.

Recycling Methods

Recycling is my top choice for handling these shafts. It not only reduces waste but also recovers valuable materials. Many companies, including those in the wind energy sector, have started to embrace recycling as a standard practice. Here’s why I think it’s essential:

- Material Recovery: Recycling allows us to reclaim metals like steel and aluminum, which can be reused in new products.

- Energy Savings: Using recycled materials often requires less energy than producing new ones from raw materials.

- Environmental Benefits: By recycling, we reduce the amount of waste that ends up in landfills, which is a win for our planet.

Proper Disposal Techniques

If recycling isn’t an option, we need to consider proper disposal techniques. Here are some recommended methods:

- Reuse: If possible, I suggest repurposing components for other applications. This can extend the life of the materials and reduce waste.

- Landfill Disposal: This should be the last resort. If the rotor cannot be recycled or reused and doesn’t contain hazardous substances, then proper landfill design and permitting are crucial. It’s important to follow industry standards to ensure safety.

By focusing on these alternative solutions, we can handle forged wind turbine shafts responsibly. It’s all about making choices that benefit both our industry and the environment.

Burying forged wind turbine shafts poses significant risks. I believe we must explore alternative disposal and recycling methods to protect our environment. The projected trends show a growing need for innovative solutions as more wind turbines reach the end of their life.

The projected trends for wind turbine shaft disposal methods over the next decade indicate a growing need for recycling and innovative disposal solutions due to the increasing number of decommissioned wind turbines.

Additionally, the wind energy industry faces challenges like fluctuating raw material prices and demand uncertainty.

- High capital intensity and technical complexity of forging operations create barriers to entry for new players.

- Fluctuations in raw material prices, especially for alloy and stainless steel, affect profit margins and pricing stability.

By focusing on responsible practices, we can ensure a sustainable future for wind energy.

Post time: Sep-12-2025