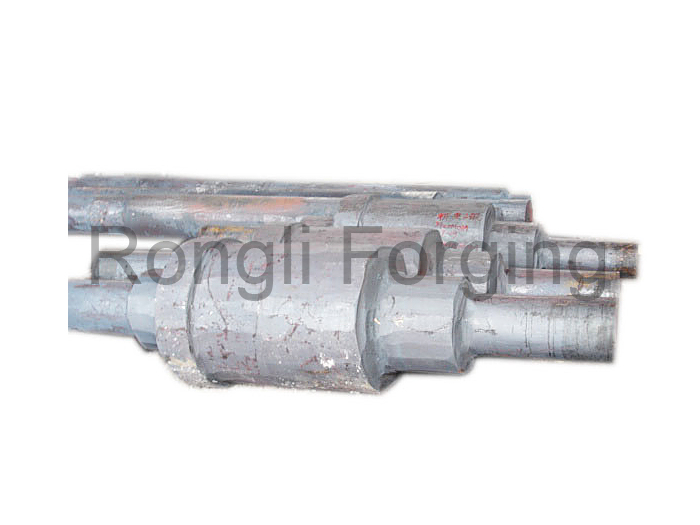

China High Quality Steel Forging Shaft Manufacturer – Forged Shaft – Rongli Forging Detail:

Introduction

Rongli Forging Co., Limited is able to supply forged & machined shaft up to 20 meters (66 feet) in length and 70 tons (44,000 lbs.) in weight. A variety of material grades to different standards are in practice here in our modernized shop. Our highly-spoken shafts are exported to North America, Europe, Australia, South Africa, in industries of Shipbuilding, power generation, mine & metal processing, heavy industry machinery, metallurgy, etc.

Material

| Standard | |||||

| North America | Germany | Britain | ISO | EN | China |

| AISI/SAE | DIN | BS | GB | ||

| 304 | X5CrNi18-10 | 304S15 | X5CrNi18-10 | X5CrNi18-10 | 0Cr19Ni9 |

| 316 | X5CrNiMo17-12-2 | 316S16 | X5CrNiMo17-12-2 | X5CrNiMo17-12-2 | 0Cr17Ni12Mo2 |

| X5CrNiMo17-13-3 | 316S31 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | |

| 1020 | C22E | C22E | 20 | ||

| 1035 | C35E | C35E | C35E4 | 35 | |

| 1040 | C40E | C40E | C40E4 | 40 | |

| 1045 | C45E | C45E | C45E4 | 45 | |

| 4130 | 30CrMoA | ||||

| 4140 | 42CrMo4 | 708M40 | 42CrMo4 | 42CrMo4 | 42CrMo |

| 4330 | 30CrNiMo | ||||

| 4340 | 36CrNiMo4 | 816M40 | 40CrNiMo | ||

| 50B | E355C | S355JR | Q345 | ||

| 4317 | 17CrNiMo6 | 820A16 | 18CrNiMo7 | 18CrNiMo7-6 | 17Cr2Ni2Mo |

| 17CrNiMo7 | |||||

| 30CrNiMo8 | 823M | 30CrNiMo8 | 30CrNiMo8 | 30Cr2Ni2Mo | |

| 30 | |||||

| 34CrNiMo6 | 817M40 | 34CrNiMo6 | 36CrNiMo6 | 34CrNiMo | |

| Plunger surfaces can be hardened with overlay welding of 2Cr13 to 45-50 HRC | |||||

Forging method: Open die forging / free forging

1. Material: Carbon steel, alloy steel, stainless steel

2. Material standard: DIN/ ASTM/AISI/ASME/BS/EN/JIS/ISO

3. Mechanical properties: According to customer requirement or standard.

4. Weight: Up to 70 Tons of finished forging. 90 Tons for ingot

5. Length: Up to 20 meters for forging

6. Delivery Status: Heat treated and rough machined

7. Industries: Shipbuilding, power generation, mine & metal processing, heavy industry machinery, metallurgy, etc.

8. Inspection: Chemical analysis with spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test are implementable.

9. Quality Assurance: Per ISO9001-2008

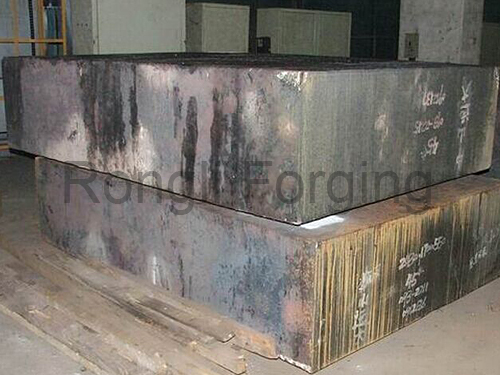

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for China High Quality Steel Forging Shaft Manufacturer – Forged Shaft – Rongli Forging, The product will supply to all over the world, such as: California, Benin, Austria, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we will continue with the most professional and high quality service to provide the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!