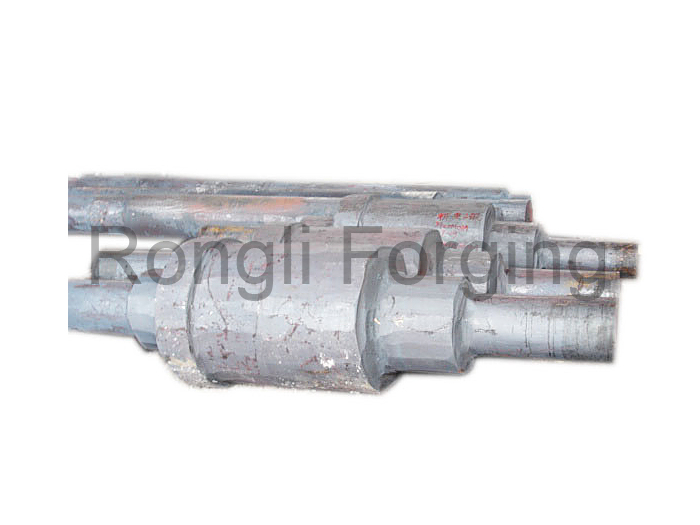

China High Quality Free Die Forging Steam Turbine Rotor Supplier – Forging Intermediate Shaft – Rongli Forging Detail:

Introduction

Rongli Forging Co., Limited has a proven track history manufacturing Steam Turbine Shafts by open die forging and green machining. Our modern shops provide us capability to forge and rough turn shafts up to 20 meters (66 feet) in length and 70 tons (44,000 lbs.) in weight, in satisfying quality to ASTM A470 or the equivalent.

Material

Rongli Forging Co., Limited has a proven track history manufacturing Steam Turbine Shafts by open die forging and green machining. Our modern shops provide us capability to forge and rough turn shafts up to 20 meters (66 feet) in length and 70 tons (44,000 lbs.) in weight, in satisfying quality to ASTM A470 or the equivalent.

| Forging method: | Open die forging / free forging |

| Mechanical properties: | According to customer requirement or standards. |

| Weight: | Up to 70 Tons of finished forging. 90 Tons for ingot |

| Delivery Status: | Heat treated and rough machined |

| Inspection: | Chemical analysis with spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test are implementable. |

| Quality Assurance: | Per ISO9001-2008 |

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for China High Quality Free Die Forging Steam Turbine Rotor Supplier – Forging Intermediate Shaft – Rongli Forging, The product will supply to all over the world, such as: United States, Jamaica, Algeria, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary items we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.