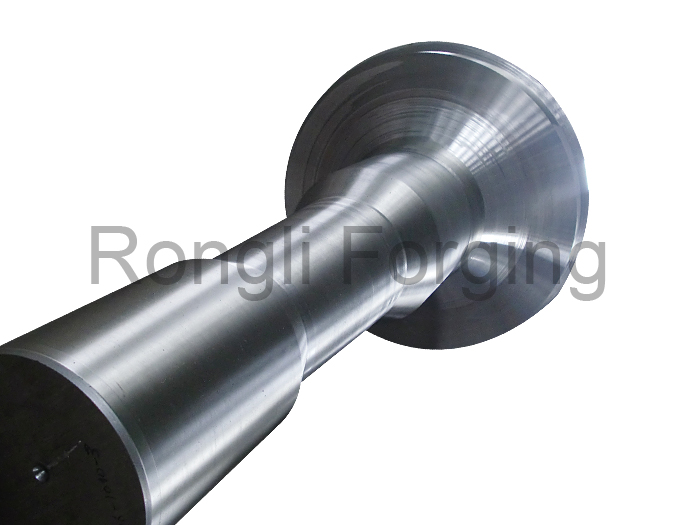

China High Quality Forging Tube Manufacturer – Forged Hollow Cylinder – Rongli Forging Detail:

Introduction

Rongli Forging Co., Limited is experienced in manufacturing hollow cylinders / tubes by open die forging and rough turning with our 2.5 m x 12 m (100” x 470”) lathe. We also provide closed-end cylinders, both with and without flanges, in various wall thicknesses and cylinder end configurations to accommodate our customers' requirements.

Material

We can accommodate customers’ requirements by applying variety kinds of carbon steel, alloy steel and stainless steel based on DIN, ASTM, ANSI, GB, BS, EN, JIS, and ISO.

| Forging method: | Open die forging / free forging |

| Mechanical properties: | According to customer requirement or standards. |

| Weight: | Up to 70 Tons of finished forging. 90 Tons for ingot |

| Delivery Status: | Heat treated and rough machined |

| Inspection: | Chemical analysis with spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test are implementable. |

| Quality Assurance: | Per ISO9001-2008 |

Product detail pictures:

Related Product Guide:

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for China High Quality Forging Tube Manufacturer – Forged Hollow Cylinder – Rongli Forging, The product will supply to all over the world, such as: Philadelphia, Honduras, Mexico, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!