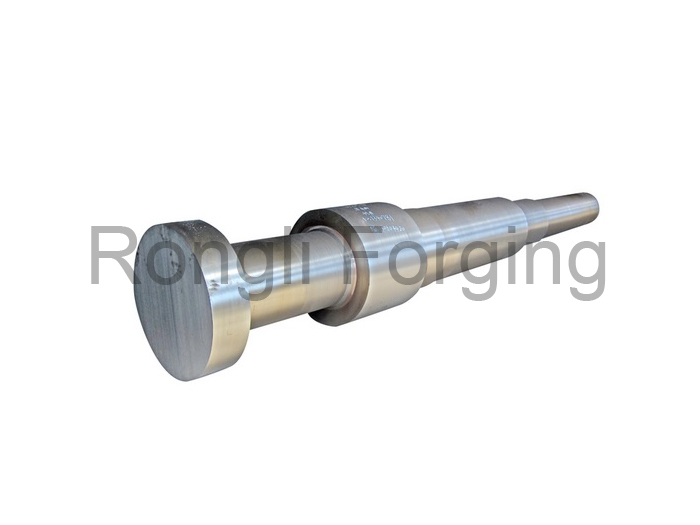

China High Quality Forged Rotor Shaft Factories – Steel forging – Heavy forging Shaft – Rongli Forging Detail:

Introduction

Rongli Forging Co., Limited is able to supply forged & machined shaft up to 20 meters (66 feet) in length and 70 tons (44,000 lbs.) in weight. A variety of material grades to different standards are in practice here in our modernized shop. Our highly-spoken shafts are exported to North America, Europe, Australia, South Africa, in industries of Shipbuilding, power generation, mine & metal processing, heavy industry machinery, metallurgy, etc.

Material

| Standard | |||||

| North America | Germany | Britain | ISO | EN | China |

| AISI/SAE | DIN | BS | GB | ||

| 304 | X5CrNi18-10 | 304S15 | X5CrNi18-10 | X5CrNi18-10 | 0Cr19Ni9 |

| 316 | X5CrNiMo17-12-2 | 316S16 | X5CrNiMo17-12-2 | X5CrNiMo17-12-2 | 0Cr17Ni12Mo2 |

| X5CrNiMo17-13-3 | 316S31 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | |

| 1020 | C22E | C22E | 20 | ||

| 1035 | C35E | C35E | C35E4 | 35 | |

| 1040 | C40E | C40E | C40E4 | 40 | |

| 1045 | C45E | C45E | C45E4 | 45 | |

| 4130 | 30CrMoA | ||||

| 4140 | 42CrMo4 | 708M40 | 42CrMo4 | 42CrMo4 | 42CrMo |

| 4330 | 30CrNiMo | ||||

| 4340 | 36CrNiMo4 | 816M40 | 40CrNiMo | ||

| 50B | E355C | S355JR | Q345 | ||

| 4317 | 17CrNiMo6 | 820A16 | 18CrNiMo7 | 18CrNiMo7-6 | 17Cr2Ni2Mo |

| 17CrNiMo7 | |||||

| 30CrNiMo8 | 823M | 30CrNiMo8 | 30CrNiMo8 | 30Cr2Ni2Mo | |

| 30 | |||||

| 34CrNiMo6 | 817M40 | 34CrNiMo6 | 36CrNiMo6 | 34CrNiMo | |

| Plunger surfaces can be hardened with overlay welding of 2Cr13 to 45-50 HRC | |||||

Forging method: Open die forging / free forging

1. Material: Carbon steel, alloy steel, stainless steel

2. Material standard: DIN/ ASTM/AISI/ASME/BS/EN/JIS/ISO

3. Mechanical properties: According to customer requirement or standard.

4. Weight: Up to 70 Tons of finished forging. 90 Tons for ingot

5. Length: Up to 20 meters for forging

6. Delivery Status: Heat treated and rough machined

7. Industries: Shipbuilding, power generation, mine & metal processing, heavy industry machinery, metallurgy, etc.

8. Inspection: Chemical analysis with spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test are implementable.

9. Quality Assurance: Per ISO9001-2008

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for China High Quality Forged Rotor Shaft Factories – Steel forging – Heavy forging Shaft – Rongli Forging, The product will supply to all over the world, such as: Liberia, Los Angeles, Ethiopia, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

-

China High Quality Heavy Forging Steam Turbine ...

-

China High Quality Forged Shafts for Fan Factor...

-

China High Quality Steel Part with Drop Hot For...

-

China High Quality Forging Ring Factories ̵...

-

China High Quality Cemented Carbide Roll Suppli...

-

China High Quality Open Die Forged Cylinder Plu...